Konstantin Grcic is no architect. Renowned for colorful, exquisitely crafted furniture, the Munich-based industrial designer has never built anything bigger than a trade show pavilion. So when the Japanese retail giant Muji tapped Grcic to develop a prefabricated hut, he figured he'd do what he does best. "My approach was that of a designer designing a building, not a designer trying to be an architect," Grcic says in a phone interview. "The concept for Muji is very much creating a building as a product, something that could be reproduced and produced in a serial way."

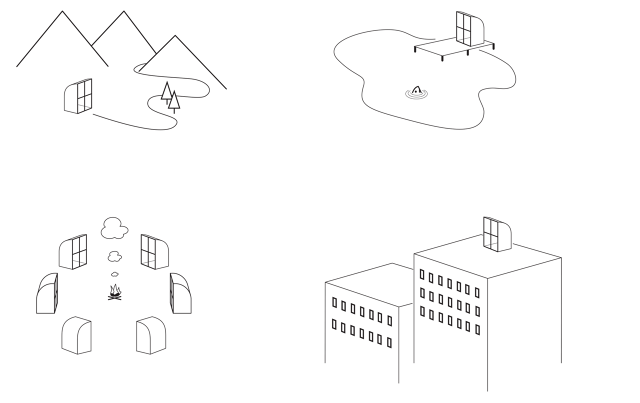

The result, a spartan 105-square-foot box with a sleeping loft, rethinks traditional notions of shelter. It doesn't have a bathroom or a kitchen. From the outside, it looks like a shed for your gardening tools as much as a place to hang your hat. The blank-slate effect is the point. "Today life is changing, conditions are changing all the time, and we have to constantly adapt to new situations," Grcic says. "Through its lifetime, a building sees so many owners and occupants doing different things. A good building is one that can adapt to different users."

A good building is also one that wastes as few resources as possible. Prefab shelters are often touted as cheaper and less resource-intensive than traditional buildings, but the reality doesn't always match the hype. So Grcic alit on a clever idea: Instead of creating a form and reverse-engineering how it could be constructed, he let the capabilities of an existing assembly line dictate the design. Fabrication first, form second.

"As industrial designers, we think about how things are made repeatedly whereas to an architect, a building is usually a prototype, a one-off," Grcic says. "Of course there are great architects who have addressed prefabrication—I don't claim to be the first one to think that way—but that approach is natural. A building is made from fabricated parts and assembled of industrial parts instead of something that's manufactured on site."

Originally trained as a cabinetmaker, Grcic is preoccupied by how things are made. "I'm always interested in seeing the factories, understanding the machinery, learning what the processes are," he says. "For me it's a fundamental inspiration, but also a kind of saying it more objectively, it's information that I think is important to know as a designer. The Muji hut has exactly this approach and the design stems from an interest in how one could build a space or shelter."

For the project, Muji held a kickoff meeting in Tokyo last March. Naoto Fukasawa and Jasper Morrison, two other designers Muji tapped to create huts, had strong ideas about what they wanted to construct; Grcic did not. As he walked around the city afterward, the simple beauty of delivery trucks caught his eye and sparked a creative breakthrough. He noticed their corrugated-aluminum cladding and corner details and started snapping photos. The best designs came from a company called Kitamura so he called up the brand and asked to see how their assembly line.

After learning more about Kitamura, Grcic was convinced that the company's assembly line would work for his hut. "Kitamura is an interesting business because it uses a system of parts that can be kind of made to measure for what you want your truck to look like," Grcic says. "That was perfect for me to use to make a building. In a way the delivery trucks are buildings—they're boxes on the back of a truck. They have all the elements of a building—a floor, a ceiling, walls, and doors. They're insulated, they are tough enough to resist weather and temperature. And the great thing is that there's an industry already making this, they have the components and they're flexible." That meant that Muji wouldn't have to create infrastructure from scratch, and pricing would be easier to calculate. What's more, existing infrastructure would help ease some of the challenges that come with working on a project from afar (Muji and Kitamura are in Japan and Grcic's studio is in Germany).

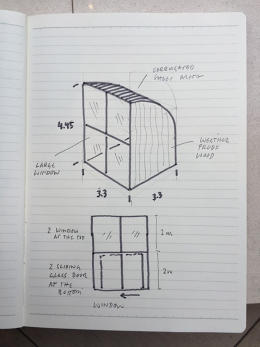

The design he came up with is essentially a shed. The Muji Hut brief called for creating "a room with a view" so Grcic translated that to its most direct sense. He didn't aim to build a prescriptive space, but opted for a flexible design that could be deployed in myriad situations. Originally, he conceived of a curved rear wall that connected with the roof, but after that proved impossible from a manufacturing perspective, he modified the design to be a tall cube. "That was a moment where I thought about what the priority is in the design," he says. "Was I doing it with Kitamura and their infrastructure? Or have I fallen in love with the curved roof?" Ultimately, he decided that the factory was the most important part of the project.

Three of the hut's sides are clad with corrugated aluminum and the fourth is composed of sliding glass doors and windows. Two massive shutters fold open to become a deck and awning. When closed, they protect the glass. The pavilion's footprint—10.8 feet by 9.8 feet—and height—16.25 feet (1.5 times the longest side)—are based on the maximum dimensions for a structure to be built without needing permits or approval from the city. The Japanese building code allowed a mezzanine inside just as long as it didn't cover more than half of the footprint, so Grcic incorporated a second level that could be used for storage or a sleeping loft.

As for not including a kitchen or a bathroom, Grcic says, "Housing issues were never driving the design, but I think in Japan, what is interesting and relevant for us to learn about is how you live in very small spaces and to make a small space feel really big," Grcic says. "I love small spaces myself. I'm interested in a small space and this idea of flexibility in how it's used."

At the hut's unveiling during Tokyo Design Week, Grcic overheard people talking about how they might use the space: as a painting studio, a storefront, a pop-up gallery. That the hut could inspire such different applications meant that it was a success in Grcic's mind. It's still in the prototype phase and very much a design in progress, but the reception proved that Grcic's underlying thought process resonated with would-be consumers. "That's what I think architecture today has to provide," he says, "the ability to adapt a space to different uses."

Generally speaking, 100% factory-built homes have proven to be equal parts alluring and elusive. The reality is that they're often just as expensive—if not more so—than conventionally built architecture. Depending on the builder's methodology, prefabs are often constructed the same way and with the same materials as a stick-built house, but the labor takes place in a controlled environment. Perhaps taking cues from non-homebuilding industries, the way Grcic has done, will make better, faster, more affordable prefabs less of a pipe dream.

The Muji huts designed by Grcic, Naoto Fukasawa, and Jasper Morrison, start at $24,000. For more information, go here.